Safety In Material Handling: The Importance of Anti-Static Bulk Bags

Anti-static bulk bags are vital because powder or granular material can generate static electric charges when being loaded or unloaded at speed from a Flexible Intermediate Bulk Container (FIBC).

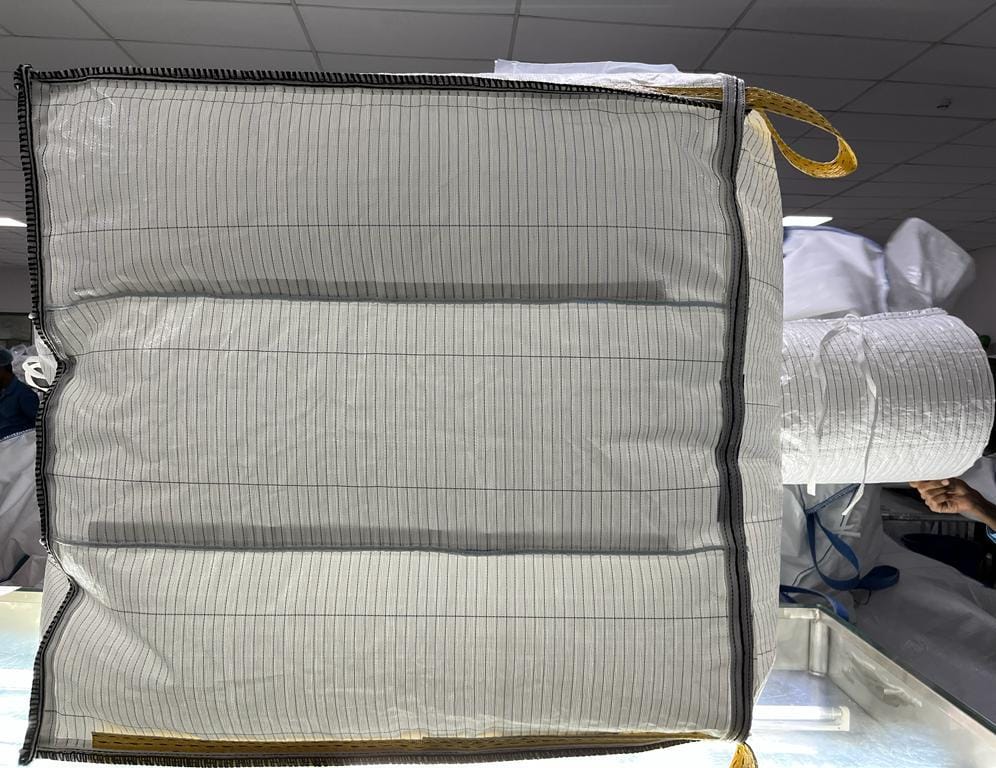

Because of this static build-up, many FIBCs are made with special fabrics that turn them into anti-static bags. Such anti-static bulk bags are typically made of polypropylene and are especially important when the loaded material is being unloaded in a combustible atmosphere.

The exact anti-static properties vary between the different types of anti-static bags, so let’s look closer at the different types and the importance of using anti-static bulk bags.

Why Anti-Static Bags Are Important

The electrostatic charges generated by filling or emptying FIBCs seek a conductive path to the ground which creates a significant ignition risk. The amount of charge generated depends on the product being loaded or unloaded, as well as the rate of filling or emptying.

One of the benefits of FIBCs is that they can be emptied very quickly, with loads between 300kg and 500kg being unloaded in 30 seconds or less. The friction between the fast-moving product and the FIBC’s fabric is what causes static electric charges to accumulate. This risk of ignition or static discharge massively increases in the presence of combustible atmospheres.

There are also multiple types of static discharge that can occur, including Spark and Brush Discharges, as well as Propagating Brush and Bulking Brush Discharges. The various types of anti-static bulk bags are designed to nullify these discharge risks.

Types Of Anti Static Bulk Bags

The three types of anti-static bags are known as Type B, Type C and Type D. The Type A bag has no anti-static properties and thus should not be used in combustible environments.

Type B anti-static bags are made with standard woven fabric that is non-conductive with low breakdown voltage. They are designed to prevent sparks and propagating brush discharges, and thus are ideal for dry flammable powders. Technically, Type B bags are not completely anti-static bulk bags because they do not dispel the electrostatic charges.

Type C anti-static bags do dispel the static via the fabric’s conductive threads. However, all the conducting panels of a Type C bag must be grounded in order to control and dissipate the electrostatic charges.

Type D anti-static bulk bags prevent incendiary sparks and brush discharges by safely dissipating the charges through low energy ‘corona’ discharges. Type D anti-static bulk bags do not need to be grounded as they are designed with special conductive threads or filaments which dispel the charges safely without grounding.

Safe Practices with Anti-Static Poly Bags

Safety is crucial in sectors that handle and transport flammable materials, such as the packaging, construction, and pharmaceuticals industries. Anti-static FIBC bags play a pivotal role in minimising the risk of fires and explosions when transporting or storing powders and granules.

The importance of safe practice with anti-static bags greatly increases in combustible environments that feature the likes of flammable vapours, gases and liquids.

If you need anti-static bulk bags such as low breakdown voltage bags or anti-static bulk bags made with protective fabric, then contact us today.